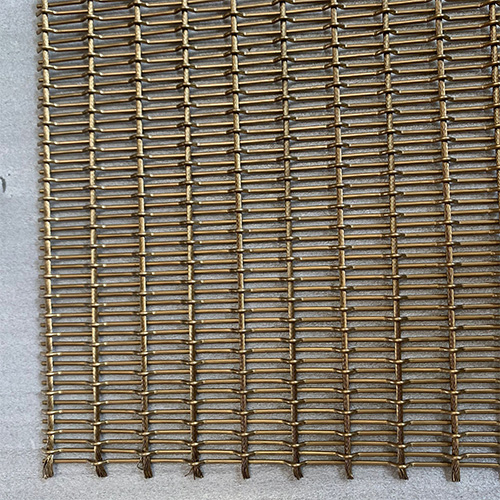

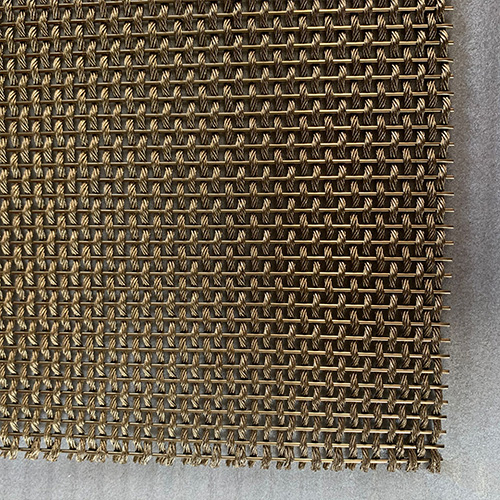

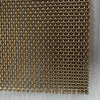

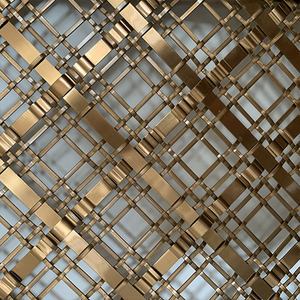

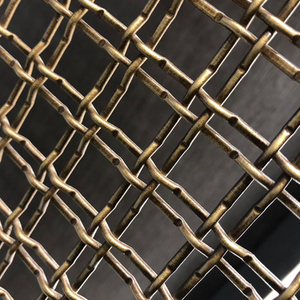

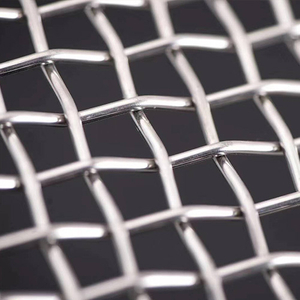

Unidirection Weave Bending Crimped Wire Mesh can be also known as the iron crimped mesh, stainless steel crimped mesh, black iron crimped mesh according to different materials.

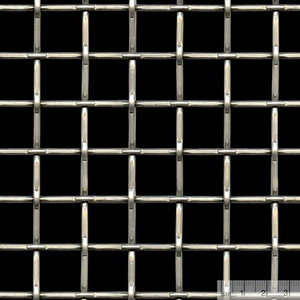

Unidirection Weave Bending Crimped Wire Mesh is made in a variety of materials through crimping mesh machine, a kind of universal wire products with square or rectangular openings.

Unidirection Weave Bending Crimped Wire Mesh Material: Iron wire, black wire, stainless steel wire(304 316 316L ect.), copper wire and other non-ferrous metal.

Pre-crimping before Weaving: one-way separated wave bending or Unidirection weav bending.

Unidirection Weave Bending Crimped Wire Mesh Features:

The special process is woven, the mesh surface is flat, the structure is firm and durable, and it is an innovative product of pig cleaning equipment. The structure is stable, the impact resistance is strong, the wear resistance is low, the cost is low, the mesh is kept uniform for a long time, and the appearance is beautiful.

Unidirection Weave Bending Crimped Wire Mesh Uses: Used for mining, coal plants, construction, petrochemical industry, construction machinery, etc.

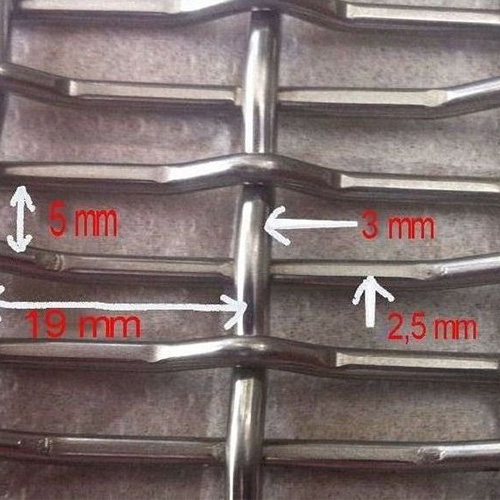

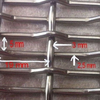

Unidirection Weave Bending Crimped Wire Mesh Specification:

Wire dia.(mm) | Mesh | Hole size(mm) | Weight: kg/m2 |

4.8 | 0.7 | 3 | 14 |

4.8 | 1 | 2 | 20 |

4.8 | 1.2 | 2 | 20 |

1.2 | 2 | 11.5 | 1.44 |

1.5 | 2 | 12.2 | 2.25 |

1.6 | 2 | 11.1 | 1.93 |

2 | 2.1 | 1 | 2.5 |

1 | 2.3 | 0.18 | 1.45 |

3 | 2.3 | 8 | 10.35 |

1.6 | 3 | 6.87 | 2.73 |

1.2 | 3 | 7.26 | 2.1 |

2 | 3.6 | 1.5 | 1.9 |

0.7 | 4 | 5.65 | 0.98 |

1.2 | 4 | 5.15 | 2.6 |

2 | 4.2 | 4 | 8.4 |

0.9 | 5 | 4.18 | 2.02 |

1 | 5 | 4.08 | 2.13 |

2 | 5 | 0.3 | 12 |

0.9 | 6 | 3.33 | 2.16 |

0.5 | 8 | 2.675 | 1 |

0.6 | 8 | 2.575 | 1.44 |

0.8 | 8 | 2.375 | 2.16 |

0.7 | 8 | 2.475 | 1.83 |

0.5 | 9 | 2.32 | 1.1 |

0.5 | 10 | 2.04 | 1.25 |

0.6 | 10 | 1.94 | 1.8 |

0.7 | 10 | 1.84 | 2.43 |

0.5 | 12 | 1.62 | 1.5 |

0.71 | 12 | 0.14 | 2.94 |

0.9 | 12 | 1.22 | 4.66 |

0.8 | 12 | 1.32 | 3.83 |

1 | 12 | 1.12 | 6 |

0.4 | 14 | 1.41 | 1.12 |

0.55 | 14 | 0.12 | 4 |

0.6 | 14 | 1.21 | 2.5 |

0.55 | 16 | 0.1 | 2.5 |

0.6 | 16 | 0.987 | 2.87 |

0.4 | 18 | 1 | 2.23 |

0.61 | 18 | 0.8 | 3.4 |

0.5 | 20 | 0.61 | 2.6 |

FAQ:

Certification: Pass CE,RoHs,GS,FDA,LFGB,3C certification.

Customize: Accept customize

Delivery Time: According to the different quantity, normal is after the payment 7-15 days

Prices: Factory direct prices ,reasonable price.

Our factory

Hebei Zhaotong Wire Mesh Manufacturing Co., Ltd. was founded in 1997. After about 23 years of development,we provide services for our clients come from more than 60 countries and regions,main product,stainless steel wire mesh,polyester printing mesh ,nylon mesh,polyester belt and wire mesh processed products.

We have 3 production factories,more than 500 employees,more than 600sets of production and testing equipment.The main production equipments: Sulzer Gripper Weaving Looms from Switzerland,JAGER BK600 weaving looms from German,JUNGENS JP-2000 weaving looms from Germany,TEXO FORMSTAR looms from Sweden,Germany Babcock heat setting machines,WIS SC-3 Automatic insertion machines from Austrian,Japan RGK-1300 metal wire mesh Automatic weaving machine,Kyoto RD Automatic Calender machine,the world’s most advanced screen productive equipments and some domestic equipments,support association in the production capacity and the level of technology equipment.

While receiving your order, we hope to provide you more technical support and system solutions plan.