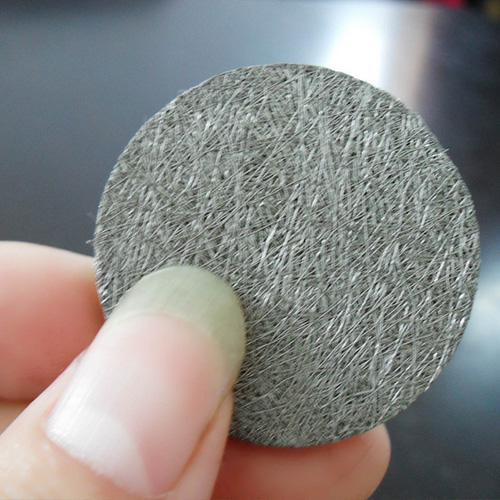

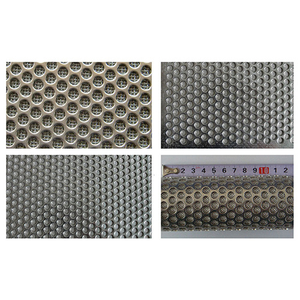

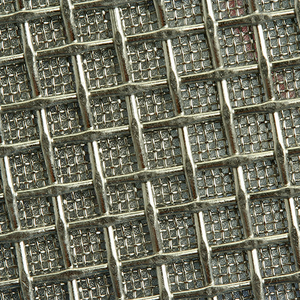

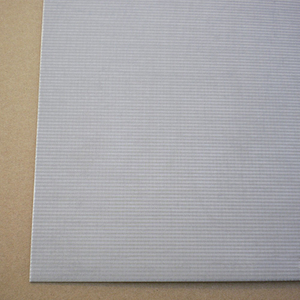

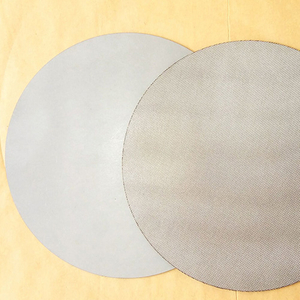

Stainless Steel Sintered Metal Felt is the use of extremely fine metal fibers made by non-woven shop, sintered at high temperature. Stainless steel sintered felt formed by different pore size pore gradient, can be controlled to obtain high filtration accuracy and greater dirt holding capacity. With three-dimensional mesh, porous structure, high porosity, large surface area, uniform pore size distribution, etc., can continue to maintain the role of filtration filter. Due to the above structure and characteristics, the stainless steel sintered felt can effectively make up for the weakness of the metal mesh and can make up for the fragility of the powder filter product and the small flow rate. The utility model has the characteristics that the ordinary filter paper and the filter cloth can not match the wet and pressure resistance, Stainless steel sintered metal felt is ideal for high temperature,corrosionresistance, high precision.

Stainless Steel Sintered Metal Felt Character:

Containing dirt capacity, high filtration accuracy, pressure rise slow, long replacement cycle

High porosity and excellent permeability, small pressure loss, large flow

Corrosion-resistant, high temperature

Easy to process, shape, weld

Our factory

Hebei Zhaotong Wire Mesh Manufacturing Co., Ltd. was founded in 1997. After about 23 years of development,we provide services for our clients come from more than 60 countries and regions,main product,stainless steel wire mesh,polyester printing mesh ,nylon mesh,polyester belt and wire mesh processed products.

We have 3 production factories,more than 500 employees,more than 600sets of production and testing equipment.The main production equipments: Sulzer Gripper Weaving Looms from Switzerland,JAGER BK600 weaving looms from German,JUNGENS JP-2000 weaving looms from Germany,TEXO FORMSTAR looms from Sweden,Germany Babcock heat setting machines,WIS SC-3 Automatic insertion machines from Austrian,Japan RGK-1300 metal wire mesh Automatic weaving machine,Kyoto RD Automatic Calender machine,the world’s most advanced screen productive equipments and some domestic equipments,support association in the production capacity and the level of technology equipment.

While receiving your order, we hope to provide you more technical support and system solutions plan.