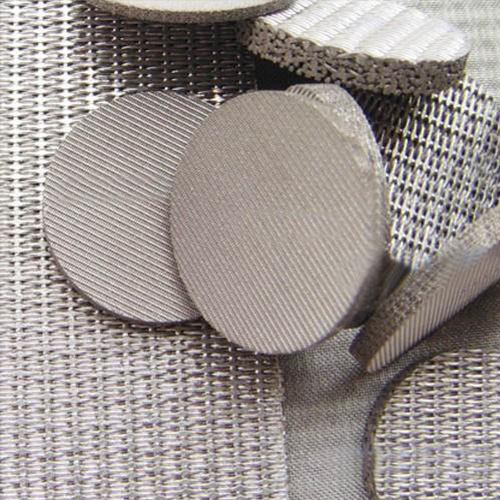

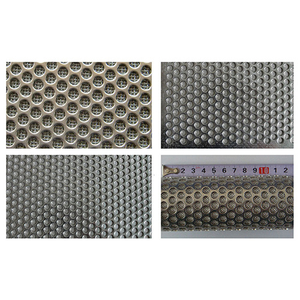

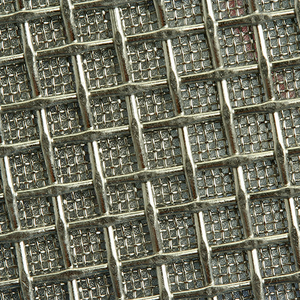

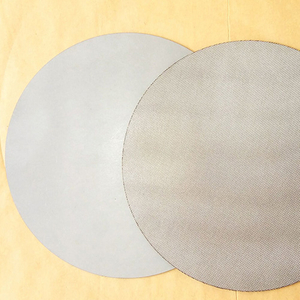

Dutch sintering mesh is a kind of two or more layers of plain weave mesh cross stacked together through sintering, pressing, rolling and other processes made of sintered net. It has a uniform distribution of mesh, breathable and stable performance characteristics. Mainly used in fluidized bed, powder delivery, muffler, drying, cooling and other fields.

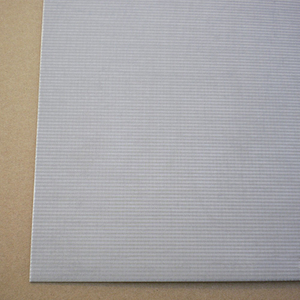

Sintered filter platesof this type are commonly used for powder delivery, laboratory fluidized beds, dryers, coolers and other solid materials. In addition, it is widely used in gas and liquid filters, chemical filters, pharmacy filters and laboratory filters.

Dutch Sintered Mesh Character:

Good rigidity, high mechanical strength

Filtering high precision, easy to backwash

Corrosion-resistant, high temperature

Standard size:500*1000mm, 600*1200mm, 1000*120mm

Standard material:316L

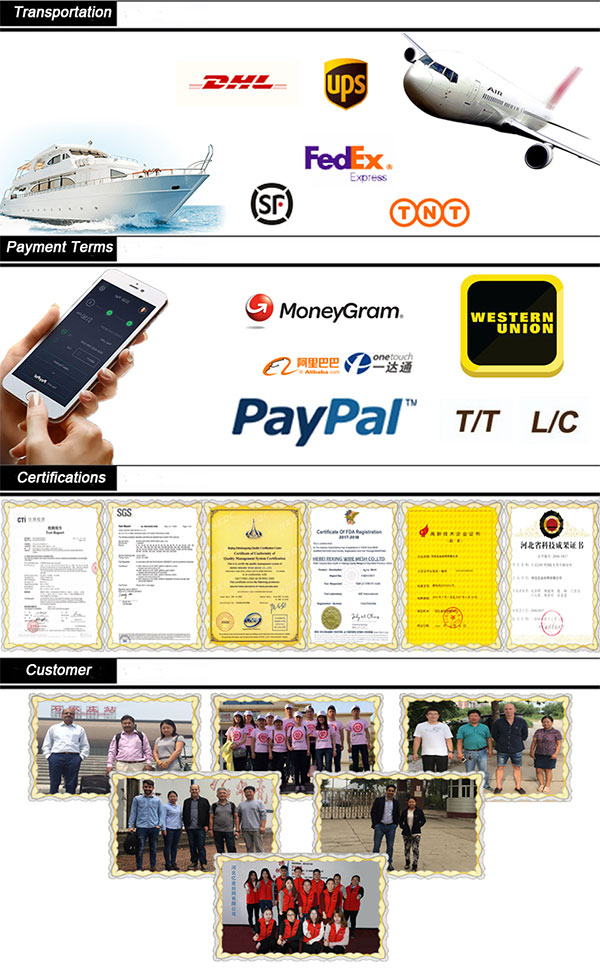

Package :

1.paper tube/Waterproof paper inside , then wooden box outside

2.Can be customized

Our factory

Hebei Zhaotong Wire Mesh Manufacturing Co., Ltd. was founded in 1997. After about 23 years of development,we provide services for our clients come from more than 60 countries and regions,main product,stainless steel wire mesh,polyester printing mesh ,nylon mesh,polyester belt and wire mesh processed products.

We have 3 production factories,more than 500 employees,more than 600sets of production and testing equipment.The main production equipments: Sulzer Gripper Weaving Looms from Switzerland,JAGER BK600 weaving looms from German,JUNGENS JP-2000 weaving looms from Germany,TEXO FORMSTAR looms from Sweden,Germany Babcock heat setting machines,WIS SC-3 Automatic insertion machines from Austrian,Japan RGK-1300 metal wire mesh Automatic weaving machine,Kyoto RD Automatic Calender machine,the world’s most advanced screen productive equipments and some domestic equipments,support association in the production capacity and the level of technology equipment.

While receiving your order, we hope to provide you more technical support and system solutions plan.