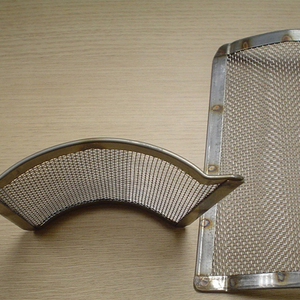

Punching net

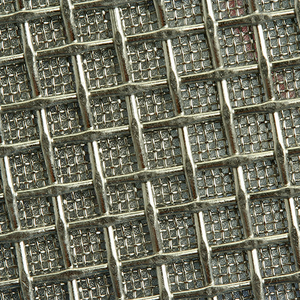

Punching nets are holes with different shapes on different materials to suit different needs. Most of the raw materials used for punching nets are: stainless steel plates, low carbon steel plates, galvanized plates, PVC plates, cold rolled plates, hot rolled plates, and aluminum plated copper plates.

Material: Most of the raw materials for punching nets are: stainless steel plate, low carbon steel plate, galvanized plate, PVC plate, cold rolled plate, hot rolled plate, aluminum plate copper plate and so on.

Type: Pattern punching net, forming punch net, heavy punch net, extra thin punch net, micro punch net, wire cut punch net, laser punch net and so on.

Punching mesh main specifications are rectangular holes, square holes, diamond holes, round holes, long holes, hexagonal holes, cross holes, triangular holes, long waist holes, plum holes, scale holes, pattern holes, character network, human character Holes, pentagonal holes, irregular holes, drum holes, shaped holes, louvered holes, etc.

1. Coil thickness 0.2mm-1mm, length 20m

2. Aperture 3mm-10mm

3. Sheet thickness 0.2mm-20mm; width * length ≤1.5m*5m

4. Aperture 0.25mm-200mm

Features

Easy to mold · Can be painted or polished · Easy to install · Eye-catching appearance · Plates of various thickness · Various choices of aperture and arrangement · Good sound absorption · Lighter weight · Longer service life · Accurate size of

Punching method

1. Continuous punching in the same direction: The use of rectangular punching nets for partial overlapping machining can be used to process long holes, trimmings, etc.

2. Continuous forming: The forming method is larger than the size of the punching net, such as large-size shutters, rolling bars, rolling steps and other processing methods.

3. Encroachment: The use of small round molds for continuous punching arcs at smaller steps.

4. Continuous punching in multiple directions: The processing method for machining large holes using a small punching net mold.

5, a single forming: According to the shape of a shallow deep-drawing molding processing.

6, a single punch: a single punching, including linear distribution, circular distribution, circumferential distribution, grid hole stamping.

7. Array forming: processing multiple pieces of the same or different workpiece processing methods on a large plate.

Defect correction

(1) Eccentricity correction occurs when punching: When the punching hole is uneven due to the anvil surface, both ends of the punch are skewed and the billet is heated unevenly, etc. The corrective method can be performed by the immersion method: during operation, the thin wall of the hole is immersed in water to lower the temperature, and then the punch is used to expand the hole. The thick side is thin due to the high temperature and good plasticity, so that the entire forging wall Uniform thickness, eccentricity is corrected. This method is suitable for plastic materials.

(2) blank deformation during punching. That is, the metal under the punch is squeezed around, the height of the blank is reduced, the diameter is increased, the upper end surface is recessed, and the lower end surface is convex. The degree of aliasing is related to the size of the billet diameter D0, height H0 and aperture d1 before punching. The smaller the D0/d1 is, the more severe the aliasing is. The corrective approach is: It is better to control D0/d1 ≥ 2.5~3. If the diameter of the punched hole is large, such as when D0/dl<2.5, the hole is generally punched first, and then the hole is bored to obtain the required hole diameter.

The main purpose

Punching nets can be used to pass environmental protection noise barriers in traffic facilities such as highways, railways, and subways in urban areas, and sound insulation panels for sound insulation and noise reduction in building walls, generator rooms, factory buildings, and other noise sources. Can be used for ceiling and wall panels of buildings, sound-absorbing sound network, horn sound materials, can be used for building stairs, balconies, beautifully decorated decorative tables and chairs, can be used for mechanical equipment protective cover, gorgeous speaker net cover, grain , sieves for feeds, mines, sieves for minerals, sieves for I-shaped words, kitchen utensils such as stainless steel fruit baskets, food covers, fruit plates, etc., as well as shelf nets for shopping malls, decorative exhibition booths, ventilation nets for grain storage, Football field lawn water filtration filter. Punching nets are also widely used in the electronics industry, such as acoustic dust cover, etc., punching nets are also widely used in chemical machinery, pharmaceutical equipment, food and beverage machinery, cigarette rolling machinery, harvesters, dry cleaning machines, ironing tables, silencing equipment , Refrigeration equipment (central air conditioning) speakers, crafts production, paper, hydraulic parts, filtration equipment and other industries.